Torsion spring

1. wire diameter as below:

0.1mm – 3.0mm wire

3.1mm – 12mm wire

12.1mm – 65mm wire

2. ISO9001:2000 certified

3. Competitive price and fast delivery

4. These springs are manufactured by fully automatic spring making machine,low cost

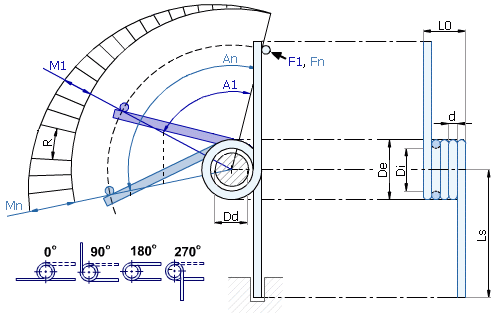

Description of parameters for Torsion springs

Physical parameters of torsion spring

d (wire diameter): This parameter describes the diameter of wire used as material for spring.

Dd (Shaft): This parameter describes maximal diameter of spring shaft in industrial applications.Tolerance for this parameter is (+-)2%(indicative).

Di (internal diameter): Internal diameter of a spring. It can be calculated by subtracting the wire diameter multiplied by 2 from the external diameter of a spring. Internal diameter in torsion springs decreases while the spring is working even up to shaft diameter. Tolerance for this parameter is (+-)2%(indicative).

De (external diameter): External diameter of a spring. It can be calculated by adding the wire diameter multiplied by 2 to the internal diameter of a spring. External diameter in torsion springs decrease while the spring is working. Tolerance for this parameter is (+-)2% with tolerance (+-) 0.1 mm

L0 (Free Length): WARNING: Free Length decrease while spring is working. Tolerance for this parameter is (+-)2%(indicative).

Ls (Leg Length): It is the distance from the center axis of the coil body to the end of the torsion springs' leg. Tolerance for this parameter is (+-)2%(indicative).

An (Maximum angle): Maximum acceptable rotation angle for the spring in degrees. Tolerance for this parameter is (+-)15 degrees (indicative).

Fn (Maximum force): Maximum acceptable force that can operate at the end of torsion springs' leg. Tolerance for this parameter is (+-)15%(indicative).

Mn (Maximum torque): Maximum acceptable torque (Newton * mm). Tolerance for this parameter is (+-)15%(indicative).

R (Spring rate): This parameter determines spring's resistance, while it is working. It is measured in Newton * mm / degree. Tolerance for this parameter is (+-)15%(indicative).

A1 & F1 & M1: (angle at torque or force) The following equation calculates the angle as a function of the torque: A1 = M1/R. In order to calculate the torque from the force, we use this equation: M = F*Ls

Leg position: There are 4 types of torsion springs' leg positions: 0, 90 ,180 or 270 degrees (see picture above).

Helix direction: A right-hand-wound spring loads in a counter-clockwise direction. A left-hand-wound spring loads in a clockwise direction. Both types are available in all sizes.

Materials of torsion spring

I (Inox steel): Inox 18/8 mark Z10 CN 18.09.

Tolerances of torsion spring

Leg position: (+-)15 degrees

Leg Length: (+-)3 %

Address: Defenghang Industrial Zone, Dongfu Town, Haicang District , Xiamen Fujian, P.R.China

Tel: +86(592)5254186 +86(592)5289710 Fax: +86(592)5513310

Email: shuangyuan@springinchina.com rosecn888@gmail.com