Tension springs

Description of parameters for tension springs

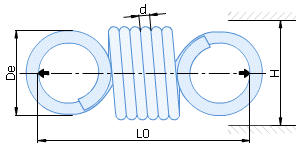

Physical parameters of Tension Spring

d (wire diameter): This parameter describes the diameter of wire used as material for spring.

De (external diameter): External diameter of a spring concerns both hooks and coils. Tolerance for this parameter is (+-)2%(indicative).

H (Hole): This is minimum diameter of hole in which spring can work. Tolerance for this parameter is (+-)2%(indicative).

Ln (Maximum length): Maximum acceptable extension length for a spring. It is also the maximum extension for static applications. Tolerance for this parameter is (+-)15%(indicative).

Fn (Maximal force): Maximal acceptable force which can operate on a spring. It is also the maximum force for static applications. Tolerance for this parameter is (+-)15%(indicative).

L0 (free length): Free length is measured in spring's free state. Tolerance for this parameter is (+-)2%(indicative).

Nr of coils: This is a total number of coils in a spring - in the picture above it is equal to six.

R (Spring rate): This parameter determines spring's resistance, while it is working. It is measured in 1 DaN/mm = 10 N/mm. Tolerance for this parameter is (+-)15%(indicative).

L1 & F1 (length under charge F): The charge F1 at length L1 can be calculated using the equation : F1 = Fn - R(Ln-L1). Equation derived from the previous for calculating L1 = Ln - (Fn-F1)/R.

Hooks: Extension springs with English hooks have both hooks closed forming a ring. Both hooks lie in the same plane.

Materials of Tension Spring

A (Music Wire): Steel that conforms to the DIN 172233 class C1 standard.

I (Inox steel): Inox 18/8 mark Z10 CN 18.09.

Tolerances of Tension Spring

maximal force: Tolerance for the maximal force is (+-)15%(indicative).

maximal length: Tolerance for the maximal length is (+-)15%(indicative).

Spring rate: Tolerance for the spring rate is (+-)15%(indicative).

Address: Defenghang Industrial Zone, Dongfu Town, Haicang District , Xiamen Fujian, P.R.China

Tel: +86(592)5254186 +86(592)5289710 Fax: +86(592)5513310

Email: shuangyuan@springinchina.com rosecn888@gmail.com