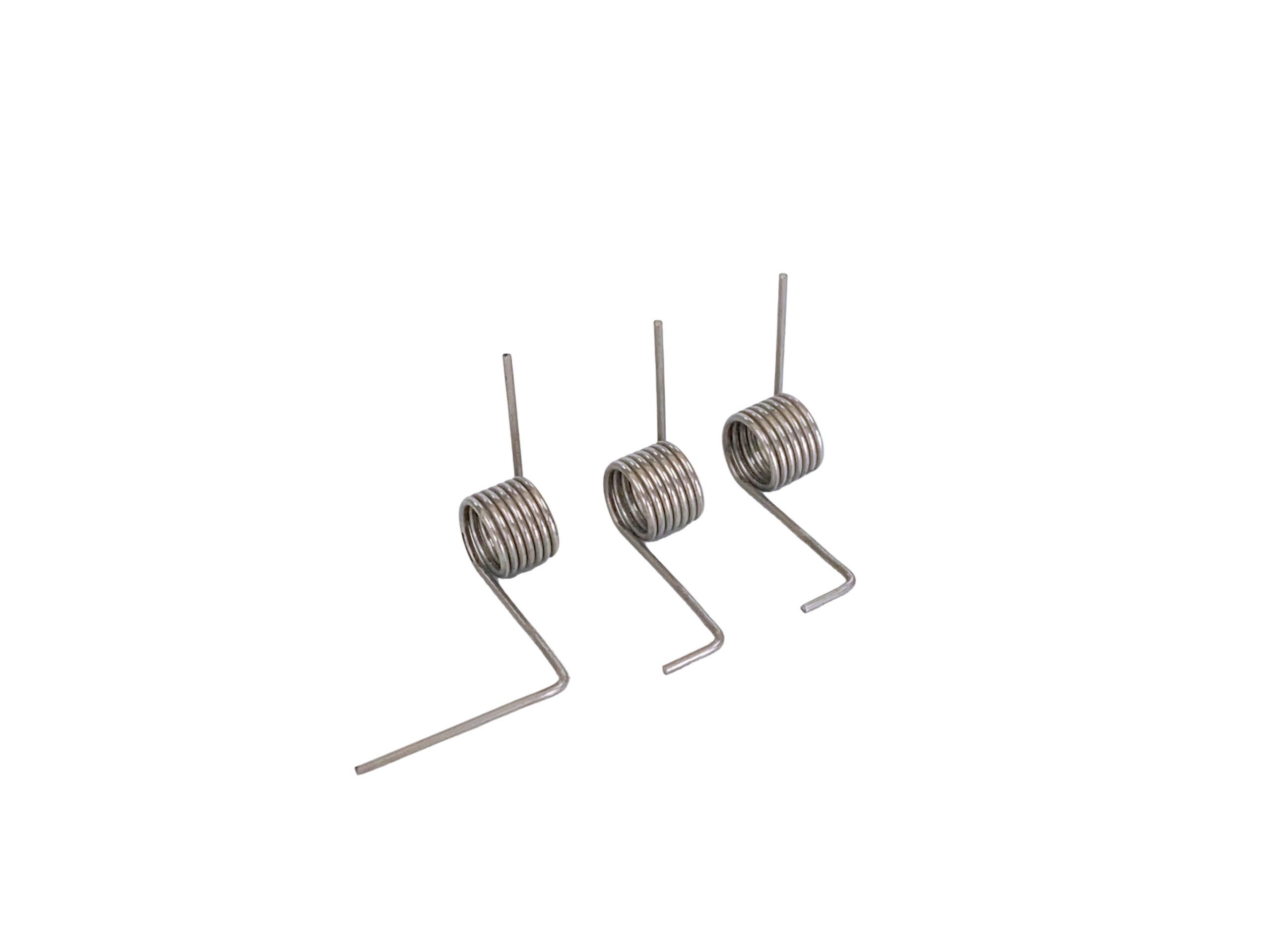

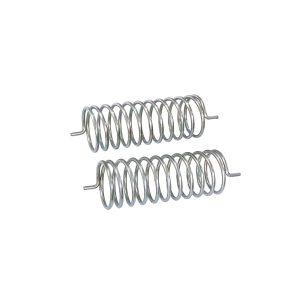

Torsion Spring

A torsion spring is a mechanical component that stores and releases energy through elastic deformation, primarily generating torque by twisting (rotating) around an axis. Here’s a detailed overview:

- Working Principle

- When one end of the spring is fixed and the other is twisted by an external force, the spring coil (usually helical) deforms elastically, storing mechanical energy.

- Upon removing the force, the spring returns to its original shape due to material elasticity, releasing torque.

- Key Features

- Motion Type: Rotates around an axis (unlike linear compression or extension).

- Torque-Angle Relationship: Torque is proportional to the twist angle (Hooke’s Law: T = k \thetaT=kθ, where TT is torque, kk is torsional stiffness, and \thetaθ is the angle of twist).

- Self-Returning: Most torsion springs automatically return to their initial position.

- Common Types

- Helical Torsion Spring: The most common type, with coils rotating around a central axis (e.g., clamps, door hinges).

- Double Torsion Spring: Combines two sets of coils with opposite winding directions for higher torque.

- Linear Torsion Spring: Combines twisting and linear motion (e.g., garage door balancing systems).

- Flat Spiral Spring: Made of flat metal strips (e.g., clock mainsprings).

- Key Design Parameters

- Material: Typically high-carbon steel, stainless steel, or music wire, requiring high elastic limits and fatigue resistance.

- Coil Dimensions: Inner diameter (ID), outer diameter (OD), and wire diameter (d).

- Torsional Stiffness (k): Torque per unit angle (N·mm/° or N·m/rad).

- Maximum Twist Angle: Safe deformation limit; exceeding it causes permanent deformation.

- Winding Direction: Left-hand or right-hand, must match installation orientation.

- Applications

- Household Items: Clothespins, mousetraps, door latch return springs.

- Industrial Equipment: Valve switches, robotic arm joints, clutches.

- Automotive: Wiper blade return mechanisms, seat adjusters.

- Electronics: Flip phone hinges, laptop screen supports.

- Selection & Considerations

- Load Calculation: Choose stiffness (k) based on required torque and twist angle.

- Fatigue Life: For high-frequency use, select durable materials (e.g., stainless steel over plain steel).

- Installation: Ensure secure anchoring to avoid stress concentration.

- Lubrication & Corrosion Protection: Coatings (e.g., zinc plating, oil) for humid environments.

- Common Issues

- Permanent Deformation: Caused by overloading or repeated twisting; requires redesign.

- Noise: Due to friction; lubrication can help.

- Fracture: Material defects or exceeding fatigue limits; upgrade to higher-strength materials.

Shuangyuan produce various tension spring with wire diameter from 0.03-16mm