Constant Force Spring

Constant Force Spring is a specially designed spring that delivers near-constant output force during extension or retraction, unlike the variable force characteristics of traditional springs. Below is a comprehensive analysis of constant force springs:

- Core Principle & Structure

- Unique Design:

Consists of a pre-stressed spiral steel strip (typically high-carbon stainless steel) tightly wound into a coil. When extended, the strip unwinds from the spool and recoils when retracted. - Constant Force Mechanism:

The change in bending radius cancels out the material’s elasticity, maintaining stable force output throughout (Hooke’s Law does not apply).

- Key Characteristics

| Property | Description |

| Force Stability | Fluctuation within ±10% across the entire range (superior to traditional springs). |

| Cycle Life | Over 10,000 cycles (material- and load-dependent). |

| Motion Direction | Configurable as tension (pull force) or compression (push force) types. |

- Typical Applications

- Office Equipment:

✦ Printer paper auto-rewind mechanisms

✦ Projector screen(lift systems) - Industrial Use:

✦ Automatic cable/hose retractors (e.g., CNC machine cable management)

✦ Constant-pressure control in safety valves - Medical Devices:

✦ Electric hospital bed height adjustment

✦ Force feedback systems in surgical instruments - Automotive Industry:

✦ Seatbelt pretensioners

✦ Anti-pinch mechanisms for power windows

- Selection & Design Guidelines

- Force Calculation:

F = \frac{E \cdot t^3 \cdot w}{6R^2}F=6R2E⋅t3⋅w

(E: Elastic modulus, t: Material thickness, w: Strip width, R: Coil radius) - Material Options:

- 301/304 stainless steel (corrosion-resistant applications)

- High-carbon steel (high-load requirements)

- Titanium alloy (aerospace/defense applications)

- Failure Prevention:

- Avoid exceeding max. displacement (typically labeled as Dmax)

- Minimum bend radius ≥ 5× material thickness

- Comparison with Traditional Springs

| Feature | Constant Force Spring | Traditional Coil Spring |

| Force Curve | Near-horizontal line | Slope (follows Hooke’s Law) |

| Space Efficiency | Flat profile saves space | Requires axial installation space |

| Dynamic Response | No resonance risk | Prone to harmonic vibration |

- Troubleshooting Common Issues

- Issue 1: End Vibration

➤ Solution: Add guide tracks or dual-spring parallel configuration - Issue 2: Premature Fatigue

➤ Solution: Switch to nanocrystallized materials - Issue 3: Force Decay

➤ Solution: Regular lubrication (molybdenum disulfide-based grease recommended)

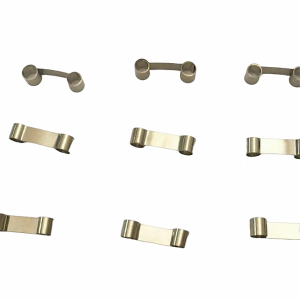

Shuangyuan produce this kind of spring with

Thickness 0.2mm~0.4mm, width 10~30, length according to customer requirements

Spring Assembly Spring Assembly